Environmental & Chemical Cleaning

Overview

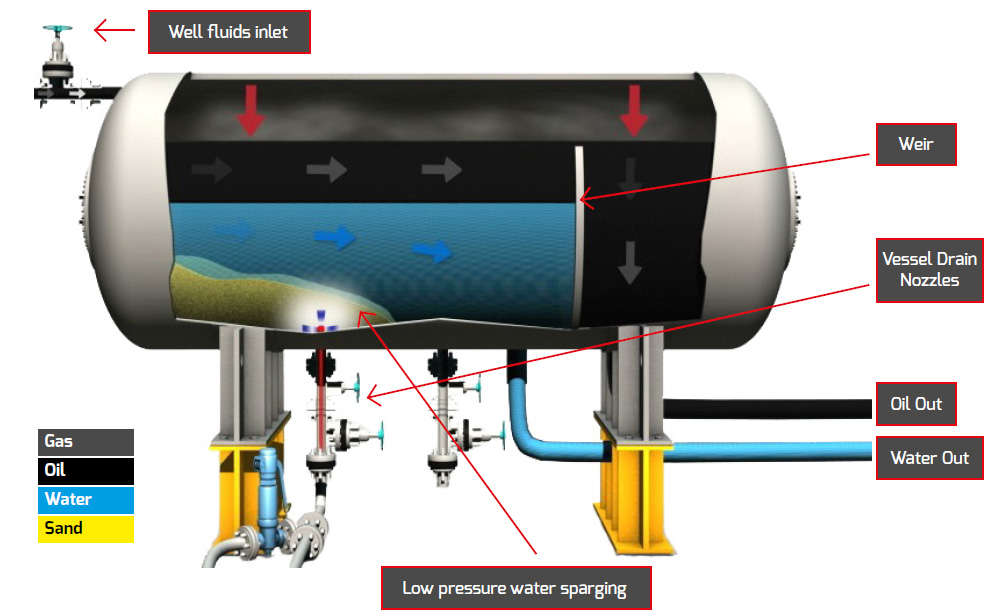

The majority of hydrocarbon reserves are contained in sandstone reservoirs, where sand production is likely to become a problem at some point during the production life of an oil or gas field. When oil or gas are produced from relatively weak reservoir rocks, small particles and sand grains are displaced enter the fluid flow – up to several tonnes of sand per day. Fluid velocities are typically high enough to transport the sand up through the well pipeline to the platform topside, accumulating in production separator vessels and production process pipelines. Produced sand is detrimental for several key reasons. When it reaches the surface, the abrasive nature of the sand can: damage valves, pipelines, pumps and separator vessels. When a significant volume of sand collects in separation vessels, the capacity of the separator to process oil, gas and water is reduced. To restore production, wells have previously been shut-in to allow the separation vessels to be opened and the sand manually removed. A critical path shutdown operation will be required and as a consequence, deferred production costs are likely for operators and the supply chain. At Altrad Industrial Services Offshore, online sand removal technology is enabling operating companies (OPCOs) to continue producing by removing the sand from the separation process without the need for a platform shutdown.

TRADITIONAL METHODS

Sand jetting systems are commonly installed in the upstream separator to remove solids that settle in gravity separators. It fluidises the solids with pressurised water introduced through specially designed nozzles. The solids are then discharged through sand drains located along the length of the vessel. The system can be arranged to flush the complete length of the vessel at the same time. These systems can be problematic as they are prone to blockages and it is very difficult to clean a blocked nozzle. Alternative systems utilising internally-installed hydrocyclone technology are common, however they are susceptible to unreliability due to changes in sand particle size and density. Separator vessels with no internal sand management devices can only be manually cleaned. This requires the shutdown of the vessel and in most cases requires the complete cessation of production on the platform. The well will be shut-in and a critical path shutdown cleaning operation required. This type of operation involves opening the vessel, and confined space entry being taken – bringing risk to personnel. In addition to the manual cleaning operation cost, the value of deferred production must be taken into account.

ALTRAD SERVICES SOLUTION

The principle of online vessel cleaning centres on inserting a water pressure hose into the belly drains of a separator to fluidise formation sand so that it is able to flow out of the vessel using the vessel’s own production pressure. A sealing gland system is used to maintain system integrity when the vessel’s in-situ valves are opened and the hose inserted. The gland is designed to withstand a high axial pressure differential, created when the vessel drain isolation valves are opened and the vessel is live.

Sand is transferred through steel conduit pipework to the Syphonvac sand management unit where the flow of material is controlled. The material flowing into the Syphonvac is dispensed into an airflow created by the Altrad Services Vacuum Transfer System. The material being deposited into collection skips by the Vacuum Transfer System for processing which can include chemical treatment, maceration and overboard disposal.

Using a thermographic camera, the sand accumulation in a separator can be determined. Thermo-imaging is used to identify the areas within the vessel where sand has settled and can indicate relative quantities.

Syphonvac is configured from two systems, one high flow vacuum and one low pressure water jetting system. These connect to the vessel discharge point via a common manifold, allowing water to be injected into the vessel via a low-pressure jetting hose whilst at the same time allowing the sand to discharge from the vessel under the vessels own pressure. The units are modular and compact, taking up a minimal deck footprint.

Altrad Services utilises bespoke jetting heads which direct the water laterally between the belly nozzles inside the base of the vessel. The jetting head will be inserted three inches into the vessel to fluidise the sand. Water is injected at regular intervals in 15-second bursts at a pressure of around 175 Barg as the sand becomes fluidised it flows into the discharge point and is directed into the common manifold. From the manifold, sand is discharged along steel conduit pipework connected to Syphonvac. This pipework is rated to 98.9 Barg (1,434psi) pressure.

Upstream of Syphonvac is a two-valve safety isolation unit. A manual choke valve is used to drop pressure and slow the solids flow and a pneumatic valve that is used to automatically isolate the Syphonvac from the vessel being cleaned in case of an emergency.

The manual safety valve is controlled by the Syphonvac operator with hand and foot controls, while the automatic safety valve can be controlled by safety systems on the platform, or by an inbuilt gas detection system, should any unforeseen changes take place.

This pressure spill back relief valve is rated to 1.5 times the vessel operating pressure.

The sand management system allows the operator to control the amount of sand discharging from the vessel using the sacrificial control valve and emergency shut off valve. The sand management system is fitted with gas sensing equipment. The gas detection system is set at a level 50% of that of the separation module. If gas is detected all other functions controlled by the system are overridden isolating the vessel from the Syphonvac system.

Thermographic checks during the online cleaning operation assist in determining when the sand has been removed from the area around the sand discharge point being utilised and prompt the operator to move onto the next available drain isolation point.

BENEFITS OF ONLINE CLEANING

Making costly platform shutdowns to remove sand from production vessels a thing of the past is the primary focus on online cleaning, and is already being proven in the field.

Reducing the risk associated with traditional man-entry to confined spaces techniques is the immediate first benefit of the Altrad’s Environmental Offshore’s system.

Operating as a safe and cost-neutral system for removing sands and sludge from production vessels, crucially it doesn’t interrupt valuable crude oil production, enhancing revenues and profitability. It also reduces sand carry-over to process systems.

Syphonvac IV can be attached to vessels operating at 40 Barg. The compact system can be moved between discharge points to access sand build-ups, also without disrupting production.

Its capability to be used prior to enforced shutdown operations to remove sand also reduces the time the asset requires to be out of service.